What do a screen door, a handrail, a recreational off-highway vehicle, and an orbital spacecraft all have in common? Chances are each of them has significant metal components that were shaped on angle rolls.

The term “angle roll” is a popular way of referring to a profile rolling machine. Profiles are long sections of metal that have a very specific shape when viewed end-on or as a cross-section. A solid round length of metal and a metal tube might look identical when viewed lengthwise, but a glance at their ends (or profiles) will identify one as a solid circle and the other as hollow. A very common profile—and the one the machine gets its name from—is angle iron. Looking at the end of a piece of angle iron will show an L-shaped profile.

A wide range of metal profiles exist, each with specific characteristics and uses. The structural member known as an I-beam literally looks like a capital I that has serifs or small strokes extending out from the top or bottom as seen in classic type styles. The flanges on an I-beam are there for support, to keep it from bending, as it would tend to do at its thinnest point under a load. Sometimes an architect or craftsman needs such a beam to be bent for aesthetic or practical reasons, however, and that is when an angle roll would be used.

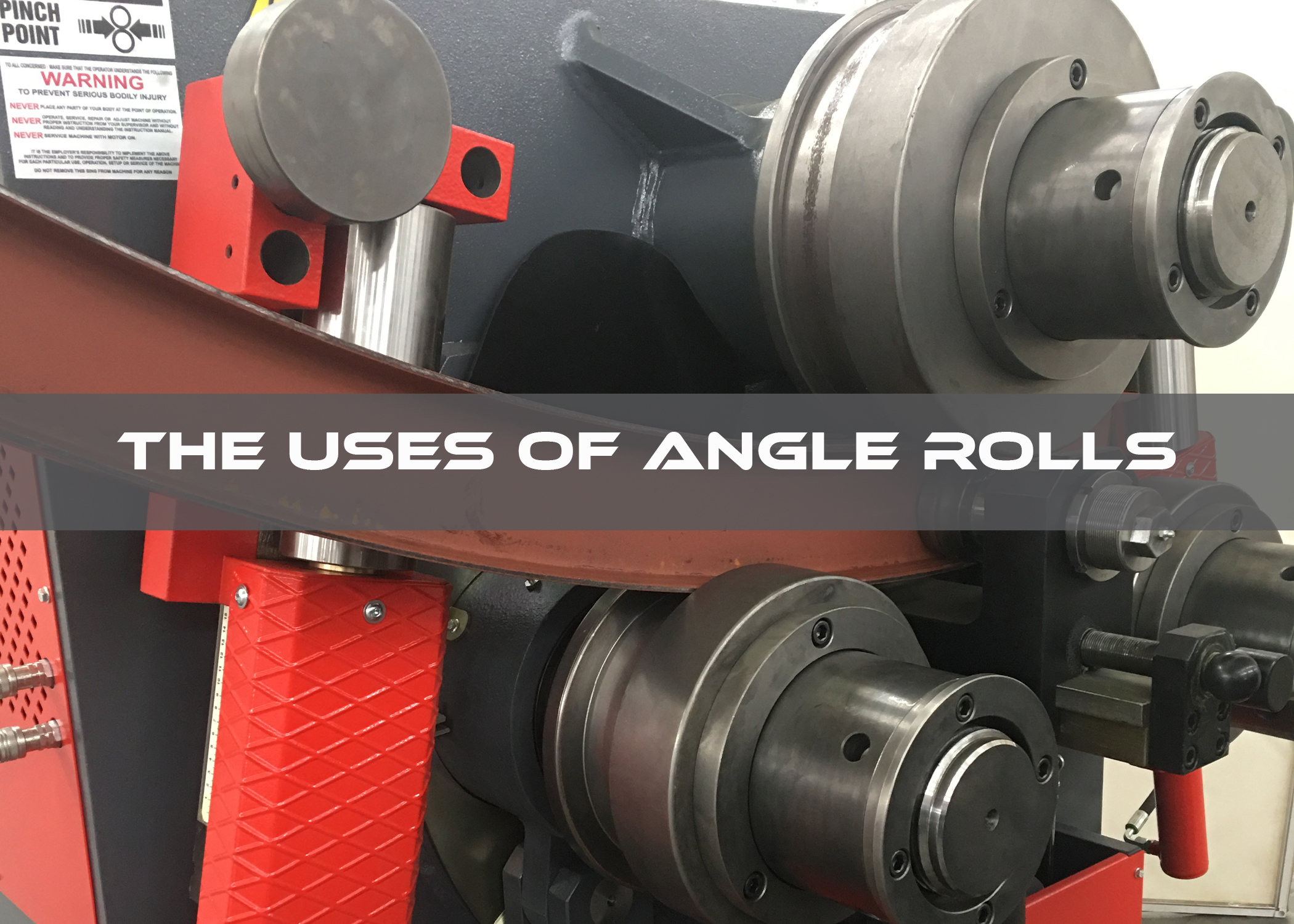

A typical angle roll will have three rolls, at least two of which are powered, and can be used to slowly form a straight piece of metal into a curved one of a specific radius or diameter. It is similar in operation to a plate roll, but instead of long rolls built to accommodate wide sheets of metal, it has short rolls that can be adapted to work with various profiles. As a piece of metal rolls back and forth between a top roll and two bottom rolls, the distance between them narrows, and immense pressure is put on the profile to make it start to curve around the top roll. The workpiece continues to move through the rolls as they slide slowly together until the final shape is realized.

Different tooling configurations exist to adapt the rolls to fit angle iron, flats, beams, round solids, round tubes, square solids, square tubes, T’s (T-shaped profiles), channels (C-shaped profiles), and many more. Angle rolls come in a wide variety of sizes, as each one has limits on how large or small it can roll due to its power and the size and spacing of its rolls. For example, a small one HP motorized machine might be able to roll 1-1/2″ by 1-1/2″ piece angle iron with a wall thickness of 3/16″ to a diameter of 24″, while a large 30 HP hydraulic angle roll might be able to roll 5″ by 5″ by 5/8″ angle iron to a diameter of 52″. An ornamental iron crafter would use a much different angle roll than someone needing to bend 20″ diameter schedule 40 pipes.

An angle roll is a versatile tool used throughout the metalworking and manufacturing industries. The types of products it can be used to create include:

- Rails and Tracks. Angle rolls can shape metal into the necessary profiles for railway tracks and tramway rails.

- Window Frames and Door Frames. They are used to produce the intricate shapes and profiles needed for window and door frames in construction.

- Automotive Parts. From chassis components to exhaust pipes, angle rolls can fabricate various parts needed in automotive manufacturing.

- Pipes and Tubes. These machines can be utilized to roll profiles for pipes and tubes used in plumbing, HVAC systems, and structural applications.

- Rolling Shutters. They are employed in creating the curved profiles required for rolling shutters used in commercial and industrial settings.

- Structural Steel Components. Beams, channels, and other structural steel components can be formed using angle rolls.

- Decorative Metalwork. These machines can shape metal into intricate and decorative designs used in architectural applications, such as ornamental gates and fences.

- Agricultural Equipment. Components for agricultural machinery, such as tractor parts and equipment frames, can be produced using angle rolls.

- Furniture Components. They can be used to create metal components for furniture, such as chair frames and table legs.

- Lighting Fixtures. They can fabricate the profiles needed for various types of lighting fixtures, including lamp posts and light poles.

As versatile as profile rolling machines are, they are only as good as the operator running them. Angle rolling is more than an operation, it is an art, and it’s essential that fabricators that work with these machines receive the proper training to allow them to perform to their peak capabilities.

From their origins in the early 20th century where they produced components used to construct the ribs of ship hulls, to modern fabrication facilities where intricate metal spirals can be produced quickly and efficiently, angle rolls have earned an honored place in metal shops and factories the world over.