Competitor or Collaborator?

A new metal fabrication business opens just blocks from your shop. What’s your first reaction? Do you feel frustration that they are crowding in on “your” territory? Are you fearful that they might win away some of your key customers? While these are natural responses, it might be more beneficial to consider how their proximity could potentially improve your margins through some type of partnership arrangement.

Competition in business is not only good—it’s essential for healthy commerce. In a free market economy, competition helps keep goods and services flowing in greater variety with higher quality and at lower prices. However, there is a concept called “competitive collaboration” that’s worth examining.

Competitive collaboration is when two or more competitors come together to work in specific areas or on certain projects that will mutually benefit all parties. Such collaborations must be carefully established to make certain everyone is on the same page regarding the goals that the businesses want to accomplish together. However, in a spirit of good will and trust—and with very clear and honest communication—a synergy between the companies can be generated that accomplishes more together than the separate firms could ever do on their own.

The benefits of competitive collaboration can include:

- Increased efficiency.

- Reduced production costs.

- Improved quality control.

- Better management of logistics.

- Joint negotiations with vendors for better deals.

- Increased innovation through combined brainstorming.

- Cross-training of personnel in different techniques.

- Ability to loan workers to each other for big projects.

- Shared marketing efforts and costs.

- Co-sponsoring events like conferences and webinars.

- Enhanced publicity and brand awareness.

- Increased market share.

Competitive collaboration gives all companies involved access to expertise and resources not otherwise readily available, with the result of helping to boost profits all around.

When It’s Time to Outsource

While your shop likely outsources projects here and there when you don’t have the proper equipment in-house, you may find additional benefits in occasionally partnering with another shop. Consider the following scenarios and see which ones might fit your circumstances.

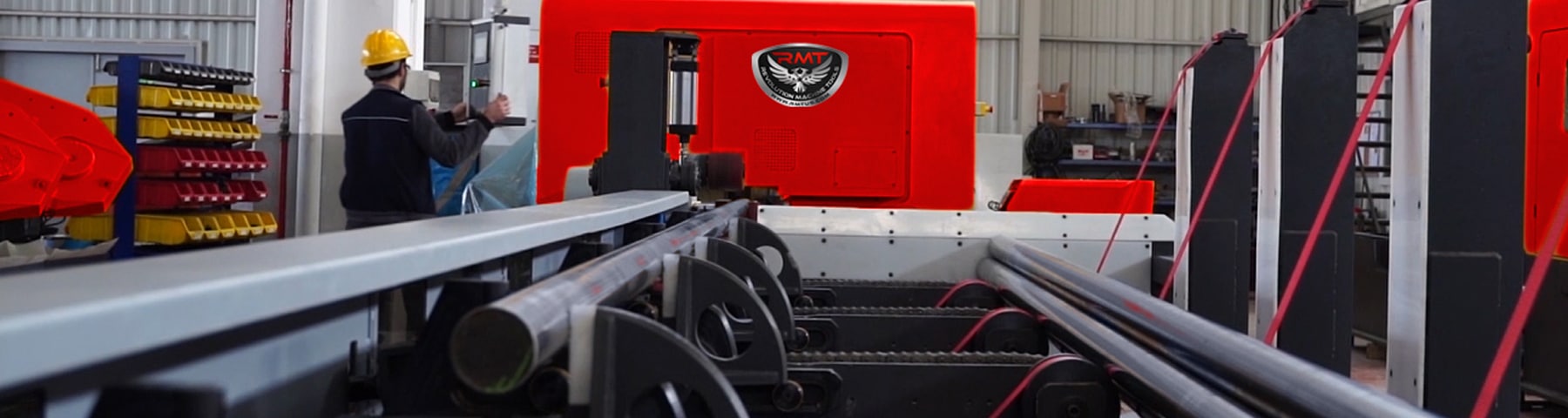

Specialization. Different shops have different specialties. Your shop might do quite a bit of welding, while another facility might own and use an advanced fiber laser. If different shops have different strengths, it only makes sense to pool resources and outsource those parts of jobs in which the other shop excels. While your ideal might be to create a “jack-of-all-trades” metal fab shop that can do everything, finding and focusing on a niche market in the local metalworking community while cooperating with other shops to draw on their strengths is a more practical solution. Once you’ve established yourself as “the shop that’s best at X,” you’ll have a competitive advantage in that field in the local market for years to come.

Additional Services. Two metal fabrication businesses could have nearly identical machines on the shop floor and yet offer other amenities or abilities significantly different from each other. One shop might provide engineering or CAD design services, another might excel in finishing work such as powder coating, and a third could have a knack for rigging and installation. From the ability to reverse engineer a product to being savvy in marketing and social media promotion, multiple fab shops offering complementary services can form beneficial partnerships that profit each other.

Large Orders. You might decide to advertise that your shop “has never met a job that we couldn’t handle,” but within a day or two of such a notice being posted someone will invariably show up with a project that is beyond the scope of what your business can manage. Planning out a contingency with another fabrication business in advance of such circumstances can keep clients happy and cash flow healthy.

Personnel Issues. Your press brake operator is out sick. What makes more sense—calling a temp agency in hopes they have a qualified replacement available, or sending a critical job to your neighboring shop, and inviting them to do the same with you under similar conditions? There may be times when you are understaffed, and it would be nice to be able to borrow some workers from another fabricator just for a day. Establishing an arrangement with another fab shop for times like those is like having additional employees available without the overhead costs of keeping them on payroll.

From teaming up to buy metal in bulk at lower prices, to having another company you can trust if you ever need a merger or a buyout, there are many reasons to consider establishing some types of partnerships with other metal fabrication shops.

Smart Partnering

It’s a great thing when two fab shops get to the point of regarding each other as assets to draw upon when needed, but it’s important to remember that regardless of all the goodwill, the other guys are still the competition.

Outsourcing, collaborating, and even loaning personnel is fine, but there should be certain boundaries established that all staff members understand and respect. The two shop owners might come to love each other like brothers, but that doesn’t mean that they should exchange their customer lists. Whether it’s proprietary techniques, pricing strategy, or even sales approaches, some details about the business simply shouldn’t be volunteered to outsiders. Information should be shared on a need-to-know basis per project and kept within those limits.

Fabrication shops that partner with each other on any projects may wish to create a comprehensive agreement outlining the parameters of what each will and won’t do. Such a contractual arrangement should list the goals of the partnership and the timetables involved, detail the extent of participation of each party and their express tasks, specify the contributions each will make in capital and other resources, detail the liability of everyone involved, and include nondisclosure and confidentiality agreements.

Collaborating with the competition could at some point mean the difference between a shop’s success or failure, so it’s something that every fabrication business should seriously consider and plan a strategy to accomplish. Even in the worst economic times, metal fabrication services are always sought after, so being flexible enough to team up with another shop might just help keep the lights on and the doors open.