A Legacy in the Making

When Kyle Jorgenson and his team of industry professionals founded Revolution Machine Tools, they were building on a legacy started decades earlier by Kyle’s father, Roger Jorgenson. Roger was a machine tool and metal fabrication equipment dealer in the Intermountain West who established a reputation of offering high quality new and used machinery while taking care to meet the needs and concerns of his customers. Growing up in the family business and learning the machine tool trade by the side of his father, Kyle brought those values of excellence in products and service with him to RMT.

The RMT team does more than just carry on a tradition, however—they are also establishing their own unique identity and heritage in the metalworking machinery industry. Most of the pieces of equipment offered by Revolution Machine Tools bear the RMT name and were designed by their R&D engineers to not only meet but exceed the expected standards in the marketplace. From press brakes to band saws to plate rolls and more, hundreds of models of machines are featured across their various lines, designated by one or two letters (such as “B” for brake), the name of the series within the line (such as FAB, SMART, GENIUS, etc.), and the model number itself. A notable exception to this nomenclature can be found in the branding of their sheet and tube fiber lasers.

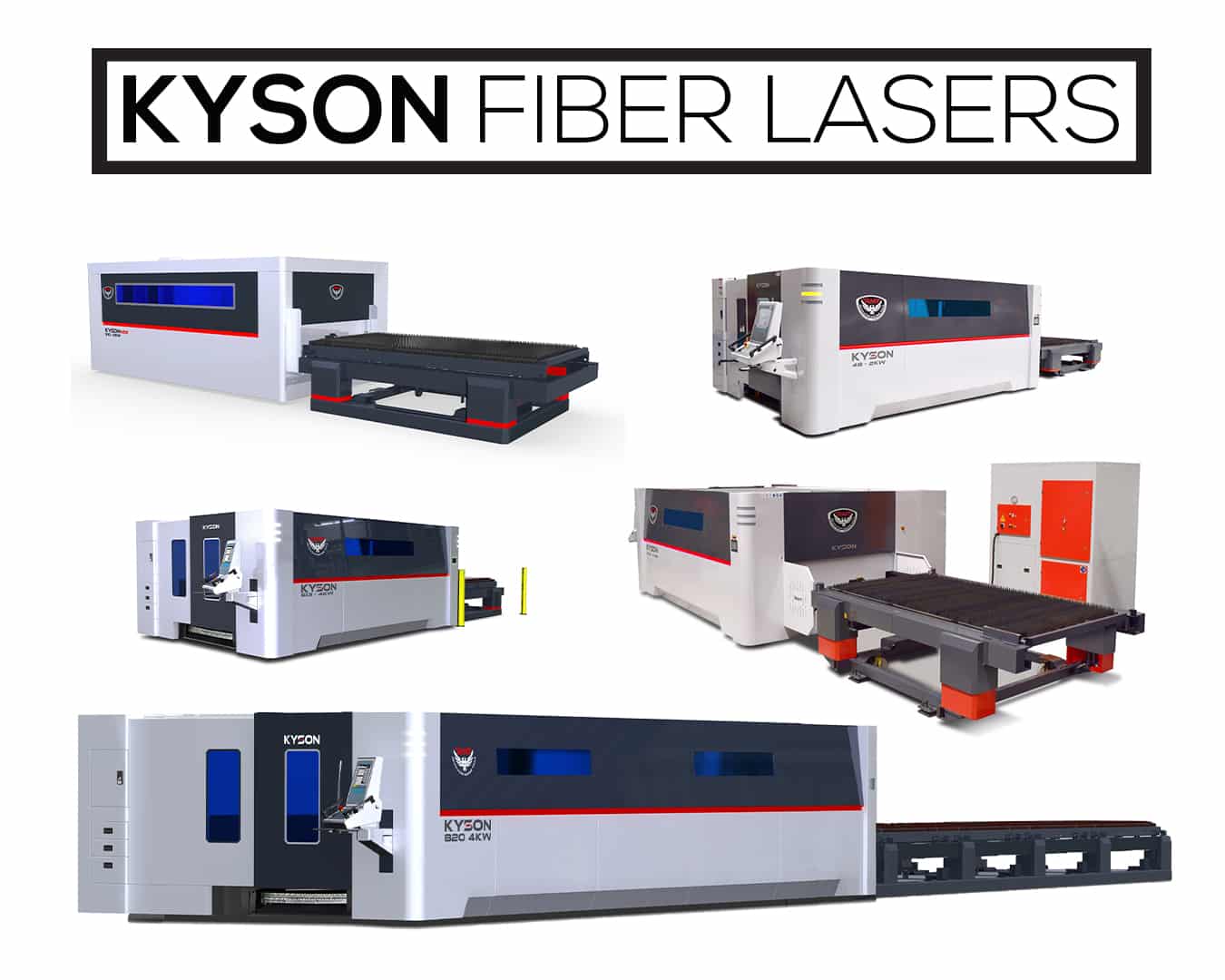

When they introduced fiber lasers to their lineup of metal fabrication machines, RMT management decided to name them “Kyson” in honor of the man who spearheaded their development—company founder Kyle Jorgenson himself. Combining cutting-edge technology with unrivaled customer service, Revolution Machine Tools offers some of the best metal-cutting lasers on the market in a range that can meet the exacting needs of almost every metalworker. KYSON fiber lasers are making their mark in an industry overrun by mediocre copycats and poor service, creating a new legacy of excellence in machine design and support.

The RMT Equipment Advantage

Like all lines offered by Revolution Machine Tools, KYSON fiber lasers have a leg up on the competition due to their design, components, and construction. Manufactured by people who use their own machines, all pieces of RMT equipment go through rigorous testing and are solidly built to withstand the rigors of daily shop use while continually providing state-of-the-art performance. In addition, unlike manufacturers who leave their customers at their mercy to buy proprietary replacement parts, RMT uses world-class components that are easily replaceable from local distributors.

KYSON sheet-cutting fiber lasers feature:

- A sturdy frame that has been carefully welded and then stress relieved through annealing, vibrational aging, and natural aging, resulting in a rigid body that lasts for decades without structural deformations that could affect operational precision.

- Critical components—such as the guide rail and the rack—that have been precisely machined by a five-axis CNC machining center for high accuracy.

- A precision cutting head with a high-power cutting system.

- An extremely user-friendly CNC unit with part checking, error recording, and real-time graphics to monitor the cutting process.

- A choice of a Radan or a Lantek CAD/CAM system for nesting and other functions, with Almacam, Metalix, Sigma Nest, and other software available optionally. (The KYSON tube-cutting lasers offer RadTube or SigmaTube CAD/CAM software.)

- Auto-changing dual tables for faster loading and unloading of blanks and parts. (A fully automatic loading and unloading system is standard on the KYSON T5X tube cutting laser.)

- Safety features including light barriers, lower protective lenses, and an auto reflection warning.

- Built-in cleaning equipment, including a nozzle cleaner, a smart slag collection system, and an automatic dust and fume removal function.

Customization is a hallmark of machines from RMT. As Kyle Jorgenson has said, “Every machine we do is a custom machine. We tailor it to exactly what the customer needs.” A case in point was when a long-time customer of Kyle’s—and Kyle’s father before him—requested a laser be built to an unprecedented length for the industry. Having never encountered a challenge that he wasn’t willing to tackle, Kyle and his team designed and engineered a 60-foot dual table fiber laser, the largest such machine in use in North America today. RMT has also developed plans for lasers up to 80′ in length, should a customer request one.

The following are the sheet-cutting fiber lasers available from RMT:

- KYSON 48 Fiber Laser. 4′ x 8′ table. 2 kW – 15 kW power.

- KYSON Falcon 510 Fiber Laser. 5′ x 10′ table. 2 kW IPG (optional 3 kW and 4 kW).

- KYSON Rebel 510 Fiber Laser. 5′ x 10′ table. 2 kW IPG (500W to 4 kW available).

- KYSON 510 Fiber Laser. 5′ x 10′ table. 2 kW – 15 kW power.

- KYSON 512 Fiber Laser. 5′ x 12′ table. 2 kW – 15 kW power.

- KYSON 613 Fiber Laser. 6′ x 13′ table. 2 kW – 15 kW power.

- KYSON 614 Fiber Laser. 6′ x 14′ table. 2 kW – 15 kW power.

- KYSON 620 Fiber Laser. 6′ x 20′ table. 2 kW – 15 kW power.

- KYSON 626 Fiber Laser. 6′ x 26′ table. 2 kW – 15 kW power.

- KYSON 820 Fiber Laser. 8′ x 20′ table. 2 kW – 15 kW power.

- KYSON 826 Fiber Laser. 8′ x 26′ table. 2 kW – 20 kW power.

- KYSON 860 Fiber Laser. 8′ x 60′ table. 2 kW – 20 kW power.

- KYSON 1060 Fiber Laser. 10′ x 60′ table. 2 kW – 20 kW power.

The following are the tube and profile-cutting fiber lasers available from RMT:

- KYSON TE4X 21-8 Tube Cutting Fiber Laser. 4-axis manual loading. 8″ x 21′ tube capacity. 1.5 kW power.

- KYSON T5X Tube Cutting Fiber Laser. 5-axis fully automatic loading and unloading. Material length capacity of 21′ in automatic (22′ in manual). Material diameter capacity of 10″ round tube, 5.9″ wide elliptical/polygonal tube, 7.875″ x 7.875″ square tube, and 5.9″ x 5.9″ angle iron. 3 kW power (4 kW available).

The RMT Company Advantage

Revolution Machine Tools understood from the get-go that offering the finest in metalworking equipment meant little if it didn’t have a dependable company standing behind every machine. Meeting the needs of customers before, during, and long after the sale is more than a goal at RMT, it has become the very mission of management and staff.

The origin of KYSON tube cutting fiber lasers is evidence of this dedication. A customer of RMT’s

asked if they could provide him with a tube laser, a product they didn’t offer at the time. Their solution? Start a new line of tube and profile cutting lasers, knowing that other customers would eventually request them. “They’re a good partner if you’re going to get into the business,” that same customer said. He contrasted Revolution Machine Tools with other manufacturers in the industry where purchasers are considered “just a number to them,” noting that “with RMT, you’re a customer, you’re a partner.”

RMT’s promise of outstanding service to its customers includes:

- Experienced machinery sales consultants dedicated to providing the very best metalworking solutions to every customer.

- Pre-sale consultations that include a site assessment of the production area to mitigate any possible problems with equipment, hookups, waste disposal, rigging, and more.

- Complete installation of all equipment and available training for operators.

- Factory-trained inhouse service techs available to respond to problems of any size.

- Long-distance troubleshooting and remote support available outside of business hours.

- Preventative maintenance plans that are customizable to a shop’s financial needs

- Expert parts and tooling specialists on staff, along with high-grade consumables, tooling, and replacement parts stocked inhouse.

- Great warranties on machines and components.

“Here at Revolution Machine Tools, our goal is to be a partner with you for the rest of our life,” said Kyle Jorgenson. “Our customers are our friends. We’re here to help you, and to help you make informed decisions, the proper decisions on an investment in a machine tool.”

The Age of the Fiber Laser

The revolution in metal cutting that is fiber laser technology isn’t going away anytime soon. If you are interested in making the most of fiber lasers in your shop or factory, why not partner with a company that offers unparalleled performance in both the machines themselves and the service backing them?

Revolution Machine Tools gives their fiber laser, press brake, and other metal fabrication equipment customers the ultimate experience in metalworking machine acquisition, maintenance, and supplies. Please give them a call today for a very competitive quote on the perfect sheet or tube fiber laser for your needs and see for yourself the RMT advantage.