Metal fabrication demands tools that are not only precise but also durable and efficient. Among the many options available for cutting metal, the cold saw stands out for certain applications. Cold saws are distinct from abrasive cutoff saws, band saws, and plasma cutters in the way they operate and the results they produce.

What Is a Metal-Cutting Cold Saw?

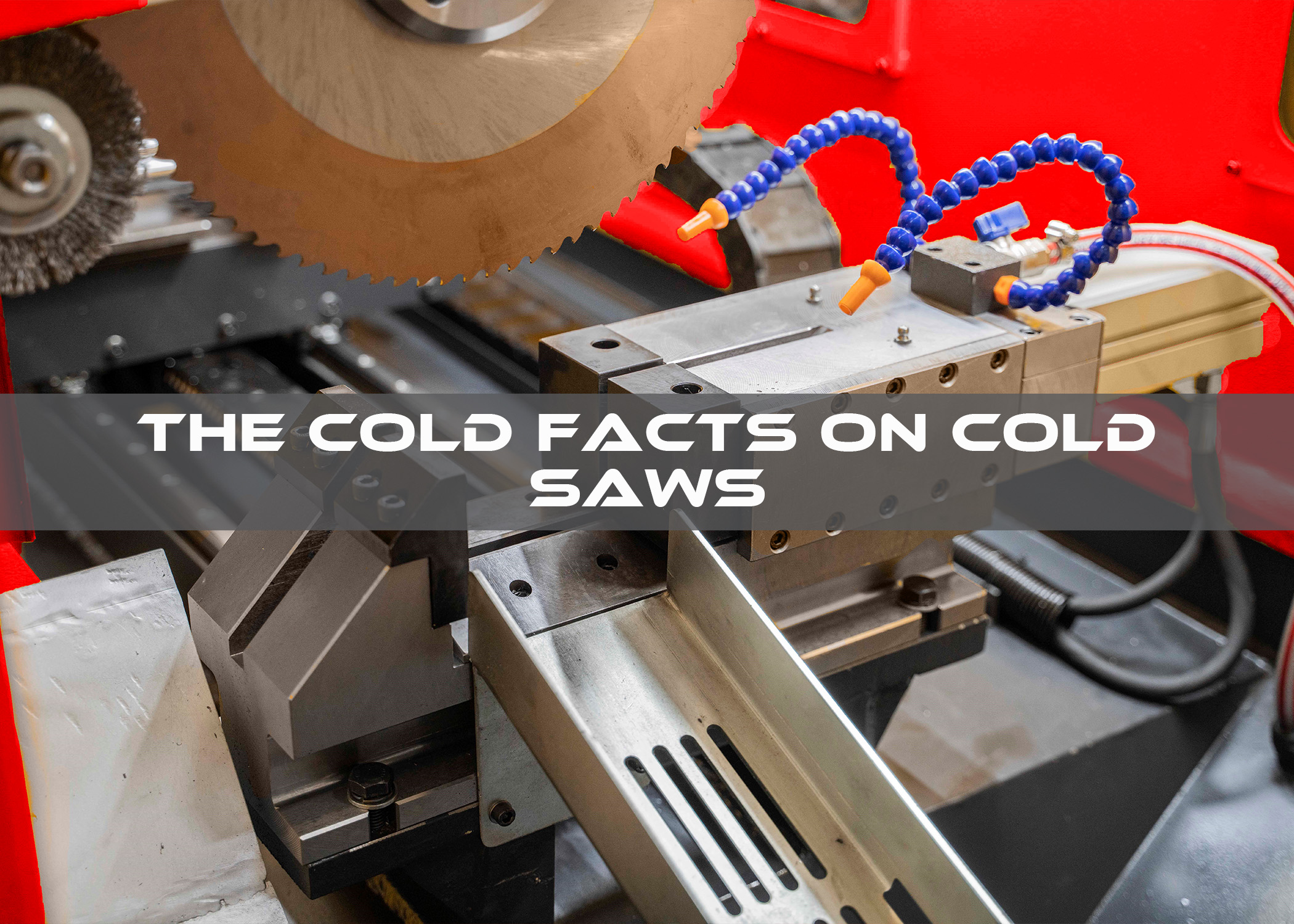

A metal-cutting cold saw is a circular saw specifically designed to cut metal using a toothed steel blade and a high-torque, low-speed motor. Unlike abrasive saws that grind through metal and generate significant heat, a cold saw shears the material with minimal friction and heat generation—hence the term “cold.” The cut surface remains cool to the touch immediately after cutting, which has several practical advantages.

Cold saws typically use high-speed steel (HSS) or carbide-tipped blades, depending on the application. HSS blades are resharpenable and offer excellent precision, while carbide-tipped blades are more durable and better suited for cutting harder materials at higher speeds.

How Do Cold Saws Work?

Cold saws function on the principle of a constant-speed, low-RPM motor that maintains high torque. This combination allows the blade to slice cleanly through metal rather than melt or abrade it. The cutting process is aided by a built-in coolant system, which further reduces heat and helps prolong the life of both the blade and the workpiece.

There are two main types of cold saws:

- Manual Cold Saws. Operated by hand, ideal for low-volume jobs or fine work.

- Semi-automatic or Fully Automatic Cold Saws. Used for high-volume production or repetitive cutting, often seen in industrial or manufacturing settings.

Benefits of Using a Cold Saw

There are several advantages to using a cold saw over other metal-cutting technologies:

- Cooler Cuts. The most significant benefit is in the name. Because cold saws cut without generating much heat, there is little thermal distortion of the material. This is crucial for maintaining tolerances and preventing microstructural changes in heat-sensitive alloys.

- Clean, Burr-Free Edges. Cold saws produce extremely smooth and precise cuts with minimal burring. This reduces or eliminates the need for secondary operations like grinding or deburring, saving time and labor.

- Blade Longevity and Sharpenability. HSS cold saw blades can be resharpened many times, which makes them cost-effective over the long term. Although carbide-tipped blades are more expensive upfront and cannot be resharpened as easily, they last much longer between replacements.

- Accuracy and Repeatability. Because the cold saw operates with minimal vibration and produces a cleaner cut, it is highly accurate and capable of repeating cuts within tight tolerances—an essential feature for parts production and fabrication.

- Reduced Sparks and Safer Operation. Unlike abrasive saws that generate a shower of sparks, cold saws are cleaner and safer to operate. The chips produced are larger and easier to manage, and the overall working environment remains cooler and less prone to fire hazards.

Limitations of Cold Saws

Despite their many advantages, cold saws do have some drawbacks:

- Cost. Initial investment is higher than for a chop saw or band saw.

- Noise. They can be loud, especially when cutting harder materials.

- Limited Cutting Area. Not ideal for very large pieces or sheet metal; better suited for bar stock, tubing, and profiles.

- Tooling Costs. Carbide blades are expensive and can be damaged if misused.

When Are Cold Saws Preferable?

Cold saws aren’t the best choice for every job. They have specific use cases where they excel, and understanding these helps determine when they are preferable over other types of metal-cutting saws.

- Precision Work in Fabrication Shops. When the job demands clean, accurate cuts, such as in structural steel fabrication or metal furniture production, cold saws are ideal. The quality of the cut reduces rework and improves overall efficiency.

- Cutting Thick or Hard Metals. Carbide-tipped cold saws are particularly well-suited to cutting through harder materials like stainless steel or thick-walled tubing. Their cutting action is cleaner and more efficient compared to abrasive saws, which may bog down or overheat.

- High-Volume Production. In settings where hundreds or thousands of identical pieces need to be cut — such as in manufacturing or metal service centers — cold saws offer consistent performance, fast cycle times, and low per-cut costs when properly maintained.

- Material Conservation. Because cold saws cut with a narrow kerf (cut width), they waste less material compared to abrasive wheels. This can be a significant benefit when working with expensive alloys or precision components.

- Working in Temperature-Sensitive Environments. Some materials, like certain alloys of aluminum or titanium, are sensitive to heat. Cold saws avoid introducing thermal stresses that could affect the material’s properties, making them ideal for aerospace or medical component manufacturing.

Choosing to Use a Metal-Cutting Cold Saw

Cold saws are an exceptional choice for cutting metal when precision, clean edges, and repeatability are essential. While they may not be the most economical tool for occasional or rough cuts, they shine in professional settings where quality and productivity matter.

Whether you’re running a high-volume fabrication shop or need ultra-precise cuts on heat-sensitive alloys, cold saws offer a powerful, clean, and efficient solution that is often worth the investment.