Aircraft rolls are long, extremely specialized sheet metal rolling machines designed largely for one specific purpose: to roll the metallic “skin” of the forward edge of aircraft wings in the correct contoured shape to properly generate lift while in flight. The shape of most wing edges will change in thickness and angle from the tip to where it joins the fuselage, so rolling the metal for the skin requires a machine that can alter the geometry of its rolls during the rolling process, unlike a simple plate roll that creates the same diameter across the length of the rolled material.

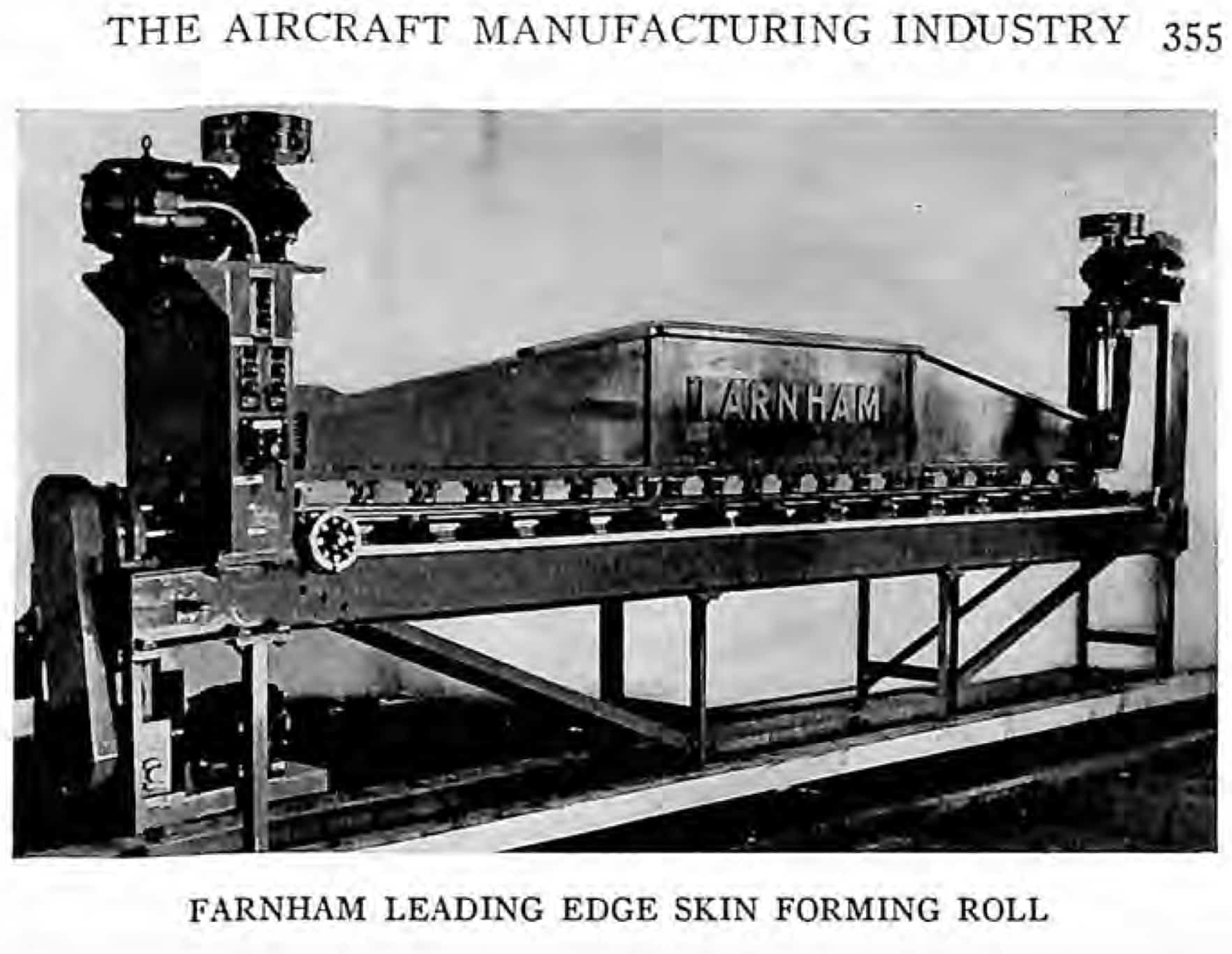

While at first glance the machine resembles a press brake with its tall, moveable ram-like structure on top, it is actually a pyramid-style three-roll machine. All three rolls can change position, with the top roll being vertically adjustable and the two bottom rolls being horizontally adjustable in relation to each other. The positions of the left and right ends of each roll are adjusted independently, allowing them to be taken out of parallel with each other in order to roll the desired contour.

While traditionally called aircraft rolls or leading-edge rolls because of their main use, these machines can also be referred to as contour rolls due to their ability to produce variety of different types of tapered parts, such as cones, and do so without additional tooling.

Origin of the Aircraft Roll

Founded in 1891 in Buffalo, New York, the Farnham Manufacturing Company had established itself in the early twentieth century as a manufacturer of paper and pulp machinery used in paper mills, along with some machine tools and construction equipment.

At the end of the great depression, with the looming possibility of the United States being drawn into World War II, Farnham began manufacturing the machine that would become its legacy.

“The Aircraft Year Book for 1941” reported, “Farnham Manufacturing Company, Buffalo, N. Y., in 1940 brought to fruition several years of experimentation with machinery designed to reduce man-hours per plane in the aircraft manufacturing industry. The year, with its tremendous expansion of the aircraft industry, created unprecedented demand for Farnham machines. After so many years of experimentation, the company was ready to deliver several types of machinery new to the industrial world. Concentrating exclusively on aircraft production requirements, Farnham increased its production tenfold during the year. By April, 1941, this production was scheduled to be doubled by addition of new facilities.”

That edition of the “Year Book” also noted that approximately 50 of the “Farnham leading edge forming rolls” had been “put in use by 21 leading aircraft manufacturers.” (“The Aircraft Year Book for 1941”, twenty-third annual edition, published by the Aeronautical Chamber of Commerce of America, Inc., page 354.)

Two years later, in the middle of the war, the same publication reported, “The machines which Farnham introduced to the aircraft industry in 1940 did much to speed up production of fighting planes.” (“The Aircraft Year Book for 1943”, page 324.)

Though the manufacture of these machines has long since ended, their name has become synonymous with this type of metal roll, leading to people in the industry often referring to them as just “Farnham rolls.” Because so few companies have built similar machines in the intervening years, used Farnham aircraft rolls remain in high demand today.

The RMT Aircraft Roll Revolution

To fill the void left when Farnham and similar aircraft rolls ceased production, Revolution Machine Tools stepped up and introduced the RMT F-Series rolls, machines that perform the same function, but are designed with powerful, unique features that improve the rolling process for both ease and accuracy.

Designed and engineered in the USA, RMT’s aircraft rolls are built to stay in production for decades, and offer the simplest, fastest and most precise wing rolling currently available for the aviation fabrication industry. They are extremely powerful and can even roll titanium-alloyed sheets with multiple radii to form perfect cylindrical, tapered or hyperbolic shapes. RMT F-Series aircraft rolls are specially designed to overcome the ultra-high yield point of titanium but are also ideal for a wide range of other materials.

With a body constructed of stress-relieved high yield steel, the RMT F-Series machine also features induction hardened, chrome coated, ground carbon steel rolls that are seated in bronze roller bushings. All rolls are driven by AC motors and helical gear boxes with cardan shafts. These dual speed aircraft rolls feature digital readouts and offer an optional NC control unit. Like all RMT machines, safety is a priority, and the F-Series includes electrical and mechanical protection against overloads and features an emergency stop cable running around the machine.

If you manufacture aircraft, always choose RMT to give you your wings!