In metal fabrication, precision is everything. Whether forming sheet metal on a press brake, rolling plate into a cylinder, or bending beams and structural sections, fabricators constantly battle the physical realities of material strength, machine rigidity, and geometry. One of the most common and challenging phenomena that occurs during these operations is deflection—the natural bending or sagging of machines and tools under load.

Deflection may sound minor, but even slight variations can lead to inconsistent bends, tapered cylinders, or parts that fail to meet tolerance. To counter this, machine builders and operators employ a technique called crowning, a controlled adjustment designed to offset deflection and ensure uniform results.

What Is Deflection in Metal Fabrication?

In engineering terms, deflection is the displacement of a structural element when a force is applied. All materials—steel, cast iron, aluminum, even hardened alloys—will bend, stretch, or compress under load, even if only by fractions of a millimeter. In metal fabrication machinery, this displacement becomes significant when forces are high, spans are long, or both.

Take the example of a press brake, one of the most common machines used to bend sheet metal. During operation, the upper tool (punch) pushes the material into the lower tool (die). This generates enormous tonnage across the length of the bed. Although the press brake is designed from heavy castings and structural steel, the ram and bed inevitably flex downward in the center because the greatest force concentrates there. The result is that the bend angle in the middle of the part is more open than at the edges, producing an unwanted “canoe” shape.

A similar situation happens in plate rolling machines. These machines bend thick plate into cylinders or cones using three or four powered rolls. Under load, the central portion of the rolls deflects, flattening slightly compared to the ends. Instead of producing a perfectly round cylinder, the result is a barrel-shaped piece with a bulge in the middle.

Deflection also shows up in beam bending, structural rolling, and even in large shears and presses. Left uncorrected, it can compromise dimensional accuracy, require costly rework, and waste material.

Why Does Deflection Occur?

Several factors contribute to deflection in fabrication machines:

- Load distribution. The applied force is rarely uniform across the machine span. The highest stresses often occur at the midpoint.

- Span length. The longer the machine bed or roll, the greater the potential deflection. A 20-foot press brake will deflect much more than a 6-foot machine under the same tonnage per foot.

- Machine stiffness. While heavier frames and larger cross-sections resist bending better, no machine is completely rigid. Even robust designs experience measurable flex.

- Material thickness and strength. Higher-strength steels or thicker plate demand greater forming forces, amplifying deflection.

Understanding that deflection is inevitable, the key is not to eliminate it (an impractical goal) but to compensate for it so that the workpiece comes out correctly.

Crowning—The Solution to Deflection

Crowning is the intentional introduction of a slight upward curve or bulge in a machine’s tools, bed, or rolls to counteract the downward or inward deflection that will occur under load. When the load is applied, the natural deflection cancels out the artificial crown, producing a straight, even result.

Think of it like pre-bending a wooden board upward before placing weight on it. Once the weight is applied, the board flattens out. In fabrication, crowning works the same way.

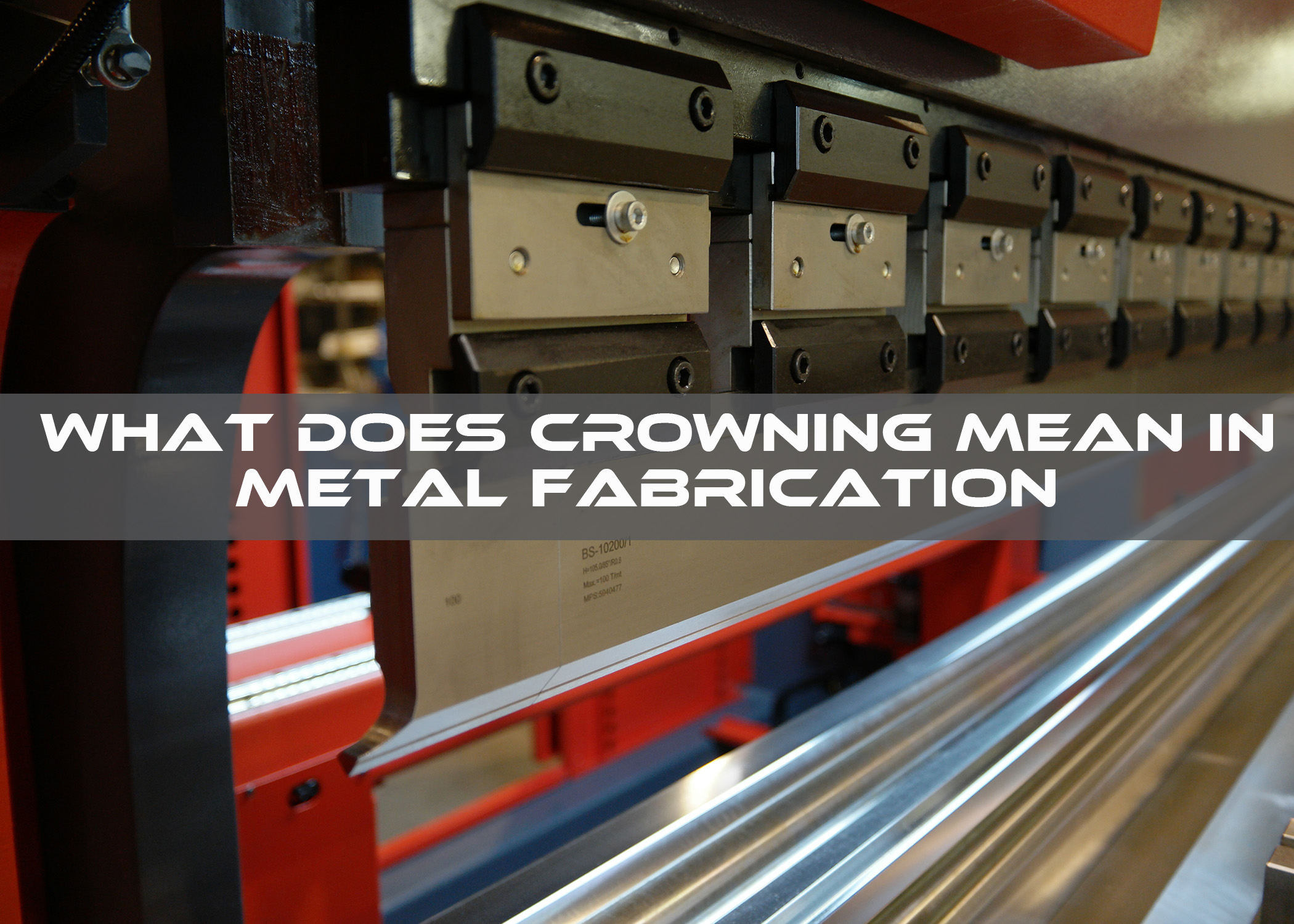

Crowning in Press Brakes

In press brakes, crowning is applied to ensure consistent bend angles across the full length of the part. Without compensation, operators would see the center of the bend open up more than the ends.

There are two main methods of crowning in press brakes:

- Mechanical crowning. The press brake bed is equipped with a series of wedges or adjustable blocks beneath the die. By turning a handle or activating a mechanical system, the operator raises the centerline of the bed slightly higher than the ends. The adjustment can be tuned for the length of the workpiece, material thickness, and applied tonnage.

- Hydraulic crowning. Modern CNC press brakes often use hydraulic cylinders integrated into the bed. These cylinders push upward in the center during bending, automatically compensating for deflection. CNC systems can calculate the required crown based on part length, thickness, and material properties, making the process precise and repeatable.

Both systems achieve the same goal: when the ram applies force and the bed deflects downward, the induced crown cancels that deflection, producing a uniform bend from end to end.

Crowning in Plate Rolls

Plate rolling machines experience deflection when the middle of a roll flattens compared to the ends. If uncorrected, the rolled cylinder becomes thicker in the middle than at the edges.

To solve this, rolls are manufactured with a pre-machined crown—a slightly larger diameter at the center than at the ends. Under load, as the rolls naturally bend inward, the center diameter equalizes with the ends, ensuring a round and true cylinder.

The degree of crown is precisely calculated based on the machine’s capacity, roll length, and expected loading. In some high-capacity or variable-use machines, adjustable crowning systems are used, but in most plate rolls, the crown is permanently machined into the rolls themselves.

Other Applications of Crowning

While press brakes and plate rolls are the most prominent examples, crowning also finds use in other metalworking equipment, such as:

- Section bending machines use crowned rolls to minimize distortion when bending beams, channels, or pipes.

- Large mechanical presses may use crowned platens or shimming systems to distribute load evenly.

- Some machine tools, like manual and CNC lathes and machining centers can also experience deflection, especially with heavy workpieces, requiring methods like shimming or proper support as a compensation technique to maintain accuracy.

In every case, the principle is the same: anticipate the deflection and design a compensating crown to cancel it out.

The Importance of Proper Crowning

Effective crowning ensures:

- Accuracy. Parts come out within tolerance without excessive trial-and-error.

- Consistency. Bend angles and radii are uniform across the workpiece.

- Efficiency. Less rework and fewer pieces of scrap saves time and material.

- Machine longevity. By evenly distributing forces, crowning reduces uneven wear and extends tool and machine life.

Without crowning, fabricators would constantly fight against physics, producing parts that are out of spec and wasting valuable resources.

A Crowning Achievement

Deflection in metal fabrication is not a flaw but a fact of life. Every press brake, plate roll, or bending machine flexes under the tremendous forces required to shape metal. The art and science of precision fabrication lies in compensating for that deflection. Through mechanical or hydraulic crowning systems in press brakes, crowned rolls in plate bending machines, or similar techniques in other equipment, manufacturers neutralize deflection and achieve straight, accurate, and repeatable results.

By understanding deflection and applying crowning correctly, fabricators turn the inevitability of machine flex into a controllable factor, ensuring quality parts and efficient production.