If you’re a serious fabricator, there are several compelling reasons to consider Revolution Machine Tools™ (RMT) as your partner in metal fabrication. Here are some of the things that set them apart from other providers:

Full-Service Capabilities and Local Roots. RMT is a full-service metal fabrication machine tool provider, handling everything from design and sales to parts, tooling, service, and ongoing support. With headquarters in North Salt Lake City, Utah, they’re well-positioned to offer timely local support, especially in the Intermountain West.

Passion-Fueled Support. RMT emphasizes a customer-first philosophy. Their passion lies in helping fabricators succeed, considering their personal successes as the true measure of RMT’s corporate success. This mindset translates into hands-on support and personalized service.

Rock-Solid Service and Warranty. The company cultivates long-term partnerships, not just transactions. They strive to have a strong service ethic, knowing that their guarantees are only as good as the team that backs them up. Many of their machines even come with a 10-year warranty, notably on press brakes. In addition, their A+ accreditation with the Better Business Bureau underscores their culture of trustworthiness and reliability.

Wide Selection and Customization. RMT offers a broad catalog of machines with impressive variety, including 88 models of hydraulic plate rolls; 75 press brake models; 62 presses; 42 shears: 31 bandsaw models; 14 models of aircraft rolls; 8 cold saws; and many more types of fabrication equipment. Revolution Machine Tools works with factories around the world to design machines to their very demanding specifications, and once the RMT name goes on them, those machines are then supported by over two dozen members of the core RMT team and a fleet of contract sellers and service personnel coast to coast. Beyond their standard offerings, they also provide customized machinery, including machines beyond 40 feet in length or over 4000-ton capacity for applications demanding heavy-duty capabilities.

High-Quality Engineering Across the Board. All their builds include world-class hydraulic and electrical components from brands like Siemens, Schneider, Mitsubishi, and Hoerbiger for reliability and easy replacement. A sampling of a few of their lines should serve to demonstrate their dedication to excellence:

- Press Brakes | Very high bending accuracy: synchronized cylinders, precise ram positioning to ±0.0004″, and high-quality Delem CNC controls. Designed for larger bends: more open height, deeper throat, longer stroke than many competitors. Fast: high approach speeds, fast bending/return, optional automation and multiple axes under CNC. Reliable: solid mono-block frames of high yield steel, backed by long warranties (10 years on standard frames). Customizable: multiple axes available (up to 14 or more, depending on the model, such as Y1/Y2, X/R servo-driven back gauges, crowning, Z1/Z2, X1/X2, R1/R2, X Prime axis [Delta X], sheet followers with sliding guides and motorized height adjustment, and front feeding systems with supports and pneumatic pushers), color/configuration options, can be custom-built to very large sizes.

- Shears | Different series tailored to different workloads and budgets: mechanical, hydraulic, CNC variable rake. Allows matching cost vs capability. Strong build: rigid construction with high-yield steel; quality cutting blades (D2 high-carbon/high chrome) suitable for a variety of materials. Precision: back gauges (with digital or CNC/X-axis, etc.), good control over stroke, support arms, safety features.

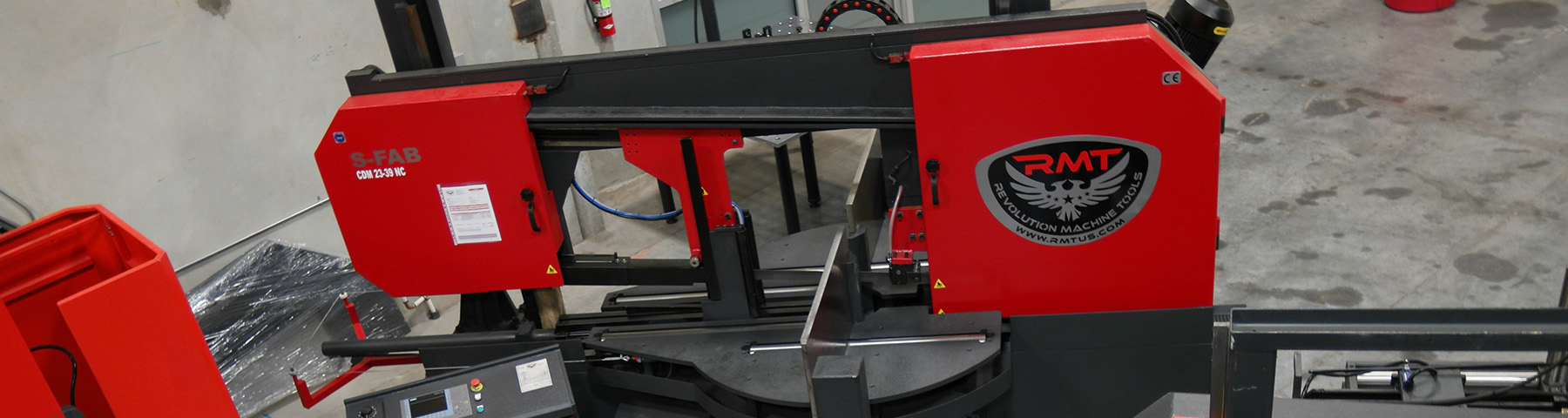

- Bandsaws | Wide automation choices: from manual and semi-automatic to fully automatic (and even “super automatic”) depending on the customer’s throughput needs. Solid standard features: NC/CNC control options, coolant systems, blade tensioning, safety features, etc. Optional features to improve cut quality, reduce blade wear, improve material handling (feeding vice, chip/lubrication systems, etc.).

- Angle (Profile) Rolls | Multiple series to suit everything from small shops up to heavy industrial: A-ECO for light/fab work, A-FAB, A-GIANT for heavy use, and CNC-driven AB-4 for high production and precision. Accuracy and Efficiency: hardened and treated rolls, good control/drive systems (all three rolls driven, precision gearboxes), well-engineered frames to preserve parallelism, etc. Flexibility: ability to roll many profiles (angles, flats, tubing, C-sections, etc.), often with “universal” tooling included. Dual orientation (vertical or horizontal) on many machines for ease of loading/handling.

Exceptional Customer Testimonials. Real-world praise speaks volumes:

- “Support… second to none, quick response and answers… lead tech guy… I flew him in to fix a press that no one else could fix, and it was up running that day!”

- “Runs better than any saw I’ve ever had. This saw kicks butt.”

- “The KYSON laser table is very user-friendly, very easy…. It’s been a great help. It’s increased our production by at least 100%…. They are always on the phone with me when I needed help.”

- “Fantastic machine. Great features. Easier to use than some of the other saws out on the market—I’ve used plenty of saws on the market—hands down the best saw.”

- “We’re very, very happy with the workmanship, the level of commitment it took to build a machine of this stature. And we’re very happy with the way RMT’s staff has taken care of us from concept to the machine landing on our floor and getting us set up and rolling.”

- “Great customer service. They stop in our shop a couple, three times a year and see if we need anything and how we’re doing.… We’re really grateful for these guys that care, come in. It’s hard to get a lot of that kind of service now in the United States.”

These remarks are just a few out of dozens of customer comments that underscore tangible confidence in RMT’s equipment and service.

The Best Possible Choice. For a serious fabricator, investing in RMT means choosing precision, consistency, and peace of mind. Their substantive product diversity, top tier quality builds, and unwavering customer support make them a formidable ally in elevating a shop’s productivity and reliability.